are knitted fabrics tested for bursting strength|how to measure fabric burst strength : distribution ChiuVetion’s HydroBurst Automatic Bursting Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the bursting strength and expansion of knitted fabric, woven fabric, non-woven fabric, laminated fabric, . 这是您成为真正的好莱坞明星的机会! 欢迎来到好莱坞故事 .

{plog:ftitle_list}

Resultado da 9 de ago. de 2023 · Assistir Gran Turismo: De Jogador a Corredor Online Dublado e Legendado - Hypeflix. ESCOLHA UMA DAS OPÇÕES .

In knitted fabrics, the greater the crochet strength of yarn loops is, the greater the burst strength of the fabric is. Moreover, yarn fineness and loop density also affect the burst strength of knitted fabrics.ChiuVetion’s HydroBurst Automatic Bursting Strength Tester utilizes hydraulic .

(In other word) Fabric bursting strength test is an alternative method of measuring strength in which the material is stressed in all direction at the same time and is therefore more suitable for such material. Example: .fabrics were tested in each of four laboratories. The fabrics were circular knit, stabilized knit and brushed knit fabrics. The components of variance for bursting strength results .

ChiuVetion’s HydroBurst Automatic Bursting Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the bursting strength and expansion of knitted fabric, woven fabric, non-woven fabric, laminated fabric, .ASTM D3786/D3786M-18 (2023) Standard Test Method for Bursting Strength of Textile Fabrics—Diaphragm Bursting Strength Tester Method. Significance and Use. 5.1 This . ChiuVetion’s HydroBurst Automatic Bursting Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the bursting strength and expansion of knitted . Outline. Add to Mendeley. Share. Cite. https://doi.org/10.1016/B978-0-323-85534-1.00017-9 Get rights and content. Abstract. Testing and analysis are the key in gauging .

ASTM D3786 – Standard Test Method for Bursting Strength of Textile Fabrics**: This ASTM International standard specifies the procedure for determining the bursting strength of woven or knitted fabrics using a hydraulic .

Bursting strength is a method of measuring strength in which the fabric is stressed in all the directions at the same time and is therefore more suitable for materials such as knitted fabrics. .

Bursting Strength of Fabric: It can be defined as the force required to rupture a woven / knitted fabric by dilating it with a force which is applied perpendicular to the plane of the sample, under standard conditions. .fabrics were tested in each of four laboratories. The fabrics were circular knit, stabilized knit and brushed knit fabrics. The components of variance for bursting strength results expressed as variance are reported in Table 1. NOTE 3—the difference in .D 1776 Practice for Conditioning Textiles for Testing2 D 3787 Test Method for Bursting Strength of Knitted Textiles—Constant-Rate-of-Traverse (CRT) Ball Burst Test3 2.2 Other Standard: TAPPI T 403, OM.91 Bursting Strength of Paper4 3. Terminology 3.1 Definitions: 3.1.1 bursting strength, n—the distending force, which isThe HydroBurst Burst Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the burst strength and expansion of knitted fabric, woven fabric, non-woven fabric, laminated fabric, elastic woven fabric, paper, and other materials when subjected to stress in both warp and weft directions, as well as in all other directions, to get the material’s burst .

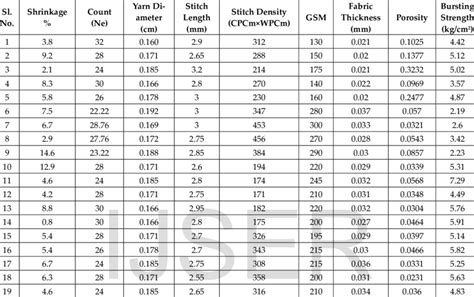

This paper investigates the bursting strength performance of single jersey weft knitted fabrics. The objective of the study is to find out the impact of the yarn count ,stitch length , stitch . 10 The type of knit structure has an effect on extensibility and strength of knitted fabrics. 11 The knitting parameters particularly yarn feeding load has an effect on fabric on fabric relaxation . In the burst strength test, the test environment also has a great influence on the BS test results, so the tester needs to choose the corresponding test environment in strict accordance with the standard. 3. Measures to be Taken to Ensure the Accuracy of the Test Results. There are many factors affecting the results of the fabric burst strength .Bursting strength is a method of measuring strength in which the fabric is stressed in all the directions at the same time and is therefore more suitable for materials such as knitted fabrics. During a test a fabric fails across the direction which has the lowest breaking extension. Tensile test is unidirectional and thus suitable for woven .

The bursting strength properties of knitted fabrics are related to the raw material, pattern type, elastomer ratio, and yarn count. . measured by bursting strength testing methods (Au 2011). 5.2 In cases where test results obtained using the procedures in Test Method D3786 have not been correlated with actual performance, Test Method D3786 is considered satisfactory for acceptance testing of commercial shipments of textile fabrics for bursting strength since the method has been used extensively in the trade for acceptance testing. In .This document describes a pneumatic pressure method for the determination of bursting strength and bursting distension of textile fabrics. NOTE ISO 13938-1 describes a method using hydraulic pressure.

5.2 In cases where test results obtained using the procedures in Test Method D3786 have not been correlated with actual performance, Test Method D3786 is considered satisfactory for acceptance testing of commercial shipments of textile fabrics for bursting strength since the method has been used extensively in the trade for acceptance testing. In .Key words: knitted fabrics, bursting strength, experimental design, Taguchi design. Taguchi views the design of a product or . The fabric bursting strength was tested Bursting Strength Tester is applied to determine the bursting strength test and distension at burst of woven, knitted and non woven fabrics,papers and boards by the application of hydraulic load .

IS 1966 (Part 1): 2009 ISO 13938-1 :1999 6.1.2 Bursting pressure shall be indicated with an accuracy of ±2 % of full scale range above the first 20 % of range. 6.1.3 Height at burst up to 70 mm shall be indicated with an accuracy of ±1 mm. Zero position of the measuring gauge shall be adjustable to accommodate the thickness of the test specimen. In case of knitted fabrics, testing and analysis are equally important to assure the quality production both during as well as postproduction. It helps to observe the faults of machinery as well as of materials throughout the process of production. . In knitted fabrics, the bursting strength tester, shown in Fig. 19.12, determines the results .

yarn burst strength

material bursting strength test

The bursting strength test is an alternative method of measuring strength and elasticity in which the material is stressed in all directions at the same time and is therefore more suitable for such a material. . Hussain, Safdar, Nazir & Iqbal. (2013).‘Optimizing the Shrinkage and Bursting Strength of Knitted Fabrics after Resin Finishing .

The pressure is increased smoothly until the test specimen bursts. The bursting strength and bursting distension are determined. 5 Sampling . For most fabrics, particularly knitted fabrics, the test area of 50 cm2 is applicable. For fabrics with low extensibility (known from previous experience or preliminary testing), e.g. for fabrics for . Tensile strength is less suitable for evaluating fabrics like knitted fabrics and lace, that when bursting strength test comes in. When the fabric is damaged, it is often subjected to pressure in the warp, weft, and oblique directions, especially some knitwear (such as weft knitted fabrics) have the characteristics of vertical extension and .

knitted fabric burst strength

FIBRES & TEXTILES in Eastern Europe 2016, Vol. 24, 2(116) Bursting strength was influenced by: n Stitch density – most compact fabrics (NP = 12.0) presented better strength for all cases due to the fact that these fabrics are characterised by a smaller stitch length and higher rigidity n Test velocity – the strength decreases with the test .

how to measure fabric burst strength

Bursting strength is a measure widely used for knit fabrics, nonwoven fabrics, and felts where the constructions do not lend themselves to tensile tests. The two basic types of bursting tests are the inflated diaphragm method and the ball-bust method. (Shah V (1998) Handbook of plastics testing technology. D6797 Test Method for Bursting Strength of Fabrics Constant-Rate-of-Extension (CRE) Ball Burst Test 2.2Standard: Other TAPPI Method T 403 . 3.1.1 The following terms are relevant to this standard: bursting strength, knitted fabric, nonwoven fabric, stretch woven fabric, woven fabric. 3.2 For all other terminology related to textiles, see . In this paper, the bursting strength of knitted fabrics was optimised using the Taguchi experiment design technique, which is a recently famous approach. This study presents the mechanical properties of weft knitted sandwich fabrics (bursting strength) and the effect of the raw materials used. Two types of fabrics, with and without reinforcing .

Scope: It tests the bursting strength of woven, knitted, or non-woven fabrics, paper, or board. Standard: GB/T7742, FZ/T60019, ISO 13938.2, NEXT TEST METHOD 22 2006, WOOLMARK TM29 2000, EDANA 80.3-99, ISO 2758, ASTMD 3786, JISL108, etc. . Fabric bursting strength tests are mainly hydraulic and pneumatic methods. The devices used are fabric .

fabric bursting strength test

The purpose of this article is to assist engineers in making quick decisions to improve the strength of single jersey knit fabric. This article focused on the different parameters of the single jersey knit fabrics (like stitch length, yarn count, GSM, tightness factor, and fabric thickness) are considered to know their influence on the bursting strength.

Resultado da Our AI model is trained on thousands of photos. This way, it renders as accurately as possible what a person would look like naked. 1 Register .

are knitted fabrics tested for bursting strength|how to measure fabric burst strength